Riser Shaft Flooring: What Are We Doing Right?

29/6/23

The riser shaft exists in every multi-storey building in the world, connecting every floor of the building. Nick Atkinson, Company Director at Ambar Kelly discusses the matter of design responsibility, which he believes is still a contested issue.

When none of the parties that work on the riser perceive its design as their responsibility, risks are created.

What is the industry doing to prevent these risks? The riser shaft starts its life as a series of holes in structural floors; one above the other. Walls are installed around the holes, then they are filled with the necessary mechanical, electrical and plumbing (MEP) services. For buildings over 18 metres according to guidelines and codes of practice these shafts should be closed off with 30-minute temporary fire doors, in addition to having temporary 60-minute passive horizontal fire protection on every fifth floor. Once the services are installed, they are closed off with permanent fire doors.

No Single Point of Responsibility

Despite the riser shaft being a key aspect of any high-rise building, there is no single point of responsibility. The present approach to riser floor

ing requires no design responsibility by the principal designer and the risk of fire through a shaft during construction is not added to the risk register to manage. This is against Construction Design and Management Regulations 2015, General Principles of Prevention - 'avoid risk in design where possible'. Evidently, when there is no single point of responsibility, substantial risks are created.

The principal contractor's role is to manage the risk, and then deliver efficient build ability through their supply chain. Subcontractors competing for the contract need a commercial advantage, resulting in risks being apportioned to separate packages. But how relevant it is to an early package in the build sequence means the focus is only on fall protection, subsequently creating a set of latent risks which are simply seen as things to manage.

The subcontractor building the structural frame becomes the designer and installer of the temporary riser protection, with the principal contractor then promoting this as the permanent riser flooring option. However, the problem is that it has not been design reviewed by the professional team, the use of differing fall protection products based on historic usage is highly problematic as it can lead to the use of combustible fall protection products in a riser shaft space. Principal designers should be designing out risk during the initial design phase and specifying riser flooring to a Euroclass A1 standard.

Non-Combustible Modular Riser Flooring

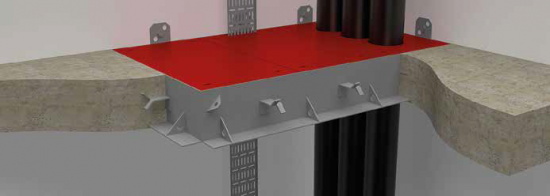

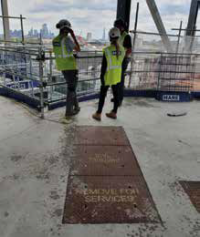

Ambar Kelly is a leading expert in riser flooring design and the manufacturer of a permanent non-combustible, modular riser flooring - RiserSafe® -

which is typically cast in to the structural frame.

Our innovative approach to riser flooring design is a completely bespoke product, which provides a single solution to the 16 separate trade packages that interconnect with the riser shaft. It also drives the coordination to incorporate the MEP services needed to complete construction of the riser shaft.

The flexible and versatile nature of the system ensures that all project requirements are met. The unique technical value of a permanent modular riser flooring system comes from having no hole (and therefore no risk) during the construction of the structural frame, through to the savings in activities in other trade package

s that interconnect with the riser shafts significantly reducing project expenses and lasting the life of the building. 3D modelling and technical support of our contracts managers enables the creation of a fully customised product, which is right the first time. Therefore, no costs are required for on site modifications.

Our philosophy is that prevention is better than cure when it comes to on site safety; the fundamental purpose of our riser flooring system. We believe that no life should ever be put at risk by falling from height or the spread of fire through construction or building use. There are many great products on the market; we would like to think ours will help on the right project and the right hole. The foundation of the right permanent riser flooring is one that simultaneously forms and protects the riser opening. This provides a physical barrier to fire and supports other required installation activities. Ultimately, this removes risk through design: no hole, no risk.

For more information on RiserSafe® and to arrange a meeting with our industry experts: Visit: www.ambar-kelly.com or call 01707 324523