Post-Tensioning for Sustainable Structures

18/11/24

As sustainability becomes a priority in construction, innovative techniques like post-tensioning (PT) are transforming how buildings are designed, built and maintained. Here Alessia Piras, Chair of the Post-Tensioning Association – considers the dual goals of reducing carbon emissions, enhancing durability and the significant advantages PT offers in sustainable construction.

Reducing Concrete's Environmental Impact

Concrete is fundamental to construction, but its production has a high environmental cost due to cement, responsible for about 8% of global CO₂ emissions. By incorporating Ground Granulated Blast Furnace Slag (GGBS), a steel byproduct, concrete's carbon footprint can be reduced considerably. Its use must be balanced with global availability constraints though, suggesting a maximum replacement of 20-30% to effectively align with sustainability goals. However, using efficient techniques like post-tensioning minimises the need for concrete in the first place, making structures both lighter and stronger.

Post-Tensioning vs. Traditional Reinforced Concrete

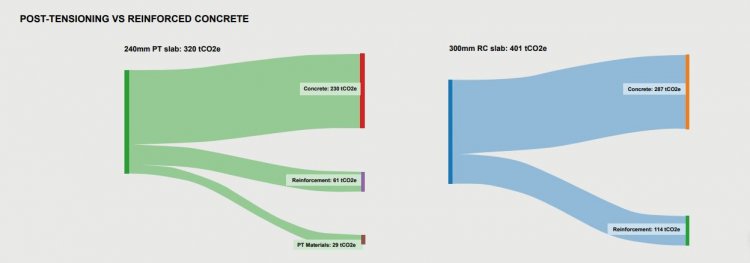

Compared to traditional reinforced concrete (RC), PT uses high-strength steel tendons to compress concrete, allowing for thinner, lighter slabs. Although PT concrete may initially show a slightly higher carbon footprint due to its mix requirements, the reduction in overall concrete and steel volume balances emissions and achieves substantial carbon savings over time.

The Sankey charts illustrate a comparison of A1-A3 carbon assessments between a 240mm PT slab and a 300mm RC slab, highlighting the carbon savings associated with the PT option. For this analysis, the following materials and Environmental Product Declarations (EPDs) were considered: C40/50 concrete with 30% GGBS (250 kgCO2e/m3), standard reinforcement steel CARES UK industry sector average (0.787 kgCO2e/kg), and standard PT strand CARES UK approved (0.76 kgCO2e/kg).

Choosing Low-Carbon Strands

The carbon footprint of PT strands can vary widely, largely depending on material sources and manufacturing methods. For example, a standard global strand may have a carbon footprint of 2.72 kgCO₂e/kg, while a CARES UK-approved low-carbon strand (Electric Arc Furnace & 100% clean energy) emits only 0.39 kgCO₂e/kg. Selecting low-carbon strands significantly enhances the sustainability profile of post-tensioned structures.

Post-Tensioning: Building for the Future

With its ability to reduce material use, increase durability, and lower emissions, post-tensioning aligns closely with the construction industry's push toward sustainable practices. By adopting PT and carefully choosing low-carbon materials, designers can contribute to a more sustainable future, ensuring that structures meet the environmental challenges of today and tomorrow.

To find out more, visit: www.posttensioning.co.uk

Source: Tall Buildings Magazine - Issue 6 by Radar Communications - Issuu